Mycotoxins are toxic substances produced by certain molds (fungi) that can contaminate various agricultural products, including animal feed. The presence of mycotoxins in animal feed can lead to reduced feed efficiency and health issues such as impaired growth, immune system suppression, and reproductive problems.

Monitoring and managing mycotoxin contamination in animal feed are critical to ensuring the health and well-being of livestock and preventing the transfer of these toxins to animal-derived food products.

In this article, specialists from Agrimprove, Agrifirm’s brand of functional feed ingredients, share their knowledge on how to properly detect the presence of mycotoxins in raw materials and processed feed.

Identifying mycotoxins in grains and feed poses a challenge due to several factors. Here, we explore the key reasons for this difficulty.

Mycotoxins are not uniformly distributed in grains or feed. Fungi growth occurs selectively, leading to varying toxin levels. This uneven distribution can start in the field and persist during storage in trucks, ships, or compartments.

Accurate analysis requires proper sampling procedures. If sampling does not represent the entire batch, results may underestimate mycotoxin concentrations. Sampling errors can lead to false negatives, so following correct procedures is crucial.

Good to know:

The chances of identifying mycotoxins in feed increase if the samples(OK?) are taken from feeders inside the farm. This is because the feed has been stored inside the farm silos for about 5 to 7 days, and for about a day in the feeders inside the rearing facility. The longer feed is exposed to the environmental conditions (high moisture and temperature) present in a farm, the greater the chance of identifying mycotoxins.

The choice of laboratory technique impacts results. High Precision Liquid Chromatography (HPLC) is more sensitive than Enzyme-Linked Immunoassay (Elisa), so lower mycotoxin levels can be detected. Advanced techniques – like Liquid Chromatography coupled with Tandem Mass Spectrometry (LC/MS/MS) – offer specificity and speed, while analyzing numerous metabolites and mycotoxins simultaneously.

The presence of these derivatives, formed during plant growth, poses a new(or: another?) challenge. Conventional tests may not detect them due to chemical changes in mycotoxin structures. Enzymes produced by plants during growth contribute to these variations. The mycotoxins adhere to other nutrients, such as sugars (glucose), fatty acids or amino acids.

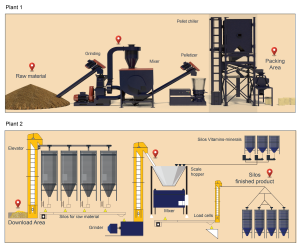

To determine which ingredients are contaminated, or when mycotoxin levels increase during feed preparation in a feed mill, it is necessary to take samples in the following areas:

To take samples from trucks or railroad cars that transport the grains to the feed mill:

| 20 – 50 MT load = 10 Kg of composite sample | 13 – 20 MT load = 6 Kg of composite sample |

|

|

| To reduce sampling variability, take two 5 kg composite samples per truck | |

|

For effective sampling at the reception area, follow this step-by-step process:

During the manufacturing process, take representative samples after grinding and before mixing. Don’t forget to continue sampling the prepared feed while it is in the storage warehouse.

To take ‘dynamic’ or moving material samples during the manufacturing process:

Tip: make sure the sampling pipe is easily accessible for cleaning. Also, wash and disinfect the sampling containers to avoid contamination.

After distributing feed on the farm, employ specific methods for accurate sampling. We recommend 2 possible methods for feeder sampling in poultry and pig farms:

or

Considering the unique challenges associated with mycotoxin detection, proper sampling techniques are crucial to obtaining accurate results. Following these guidelines ensures a comprehensive and representative analysis, contributing to effective mycotoxin management in grains and feed.

More information on mycotoxin management can be found on the website agrimprove.com.

Would you like to be kept informed of our latest developments? Register here and stay up to date.

"*" indicates required fields

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |