When exposed to stress, molds produce mycotoxins as a natural defense mechanism. The presence of these mycotoxins may vary greatly since the development of molds in the field (Fusarium) or during storage (Penicillium or Aspergillus) depends on several factors. Since mycotoxins can be produced from the field to feed, it is difficult to estimate the exact extent of feed impacted. Therefore it is recommended to regularly sample the feed, both when fungal and/or mycotoxin contamination is expected and as a prevention tactic.

In general, environmental conditions—heat, water, and insect damage—cause plant stress and predisposes plants in the field to mycotoxin contamination. Unfortunately, weather conditions are difficult to control and monitoring of the crop should be applied to predict mold presence in the plant. Even when growing conditions are perfect, feedstuffs can be contaminated pre- or post-harvest. An area where there is some ability to control against mold growth and mycotoxin formation is storage management. After harvest, temperature, moisture content, and insect activity remain the major factors influencing mycotoxin contamination of feed grains and foods. Storage conditions should be very well fine-tuned to avoid mold growth.

For animals, intoxication by mycotoxins occurs by eating contaminated feed. Since mycotoxins are usually not degraded during heat treatments or digestion, these compounds can accumulate to high doses in complete feed products; in this way posing a serious risk for animals. Many symptoms are associated with mycotoxin intoxication (mycotoxicosis), most of which are well described in animals.

Mycotoxicosis can occur at 2 levels:

Because of the serious health risks, it is very important to monitor mycotoxin levels during the feed production chain. Monitoring involves a correct sampling method as well as an accurate detection technique.

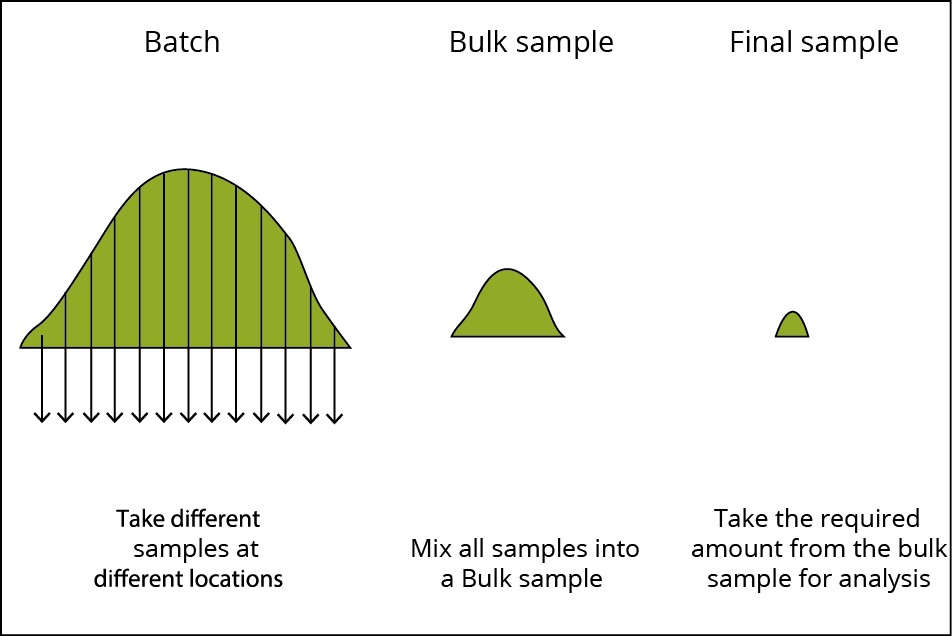

Molds (and therefore also mycotoxins) never have a homogeneous distribution pattern. Often point source contamination, or ‘hot spots’, occur in the field or during storage. Therefore, some parts of the feed or the raw material will be free of mycotoxins whereas other parts will have very high values. Traditional methods of sampling and sample preparation of agricultural crops are usually not adequate for mycotoxin analyses because mycotoxin contamination is heterogeneous.

Therefore, obtaining a representative sample is extremely important. The highly non-uniform distribution of mycotoxin contamination requires a sampling plan that takes this heterogeneity into account (Figure 1). The number of incremental samples to be taken depends on the weight of the lot and the kind of feed material that is sampled.

In the EU, and elsewhere, guidelines have been set for maximum allowable mycotoxin content in feed and feed materials. However, in practice, problems of mycotoxicosis often occur below these guidelines. There are several plausible explanations for this. First, a mycotoxin is rarely present on its own.

Second, a combination of different mycotoxins can have a synergistic effect. Third, plants are capable of rapidly modifying some mycotoxins. These modified (masked) mycotoxins often escape assays but are converted into harmful precursors again in the animal.

Finally, the effect of mycotoxin will depend on the immunity status and stress level of the animal. All this together, depending on the toxin and animal species, results in the practical maximum values being 2 to 5 times lower than the official guidelines.

| EU (ppb) | Practical when present alone | Practical when others present | |

| Aflatoxin | 10/20a | 10/20a | |

| Deoxynivalenol (DON) | 900 | 300 | 200 |

| Zearalenone (ZEA) | 100/250b | 80 | 50 |

| Fumonisin (B1 + B2) | 5,000 | 2,500 | 1,500 |

| Ochratoxin | 50 | 50 | 30 |

| EU (ppb) | Practical when present alone | Practical when others present | |

| Aflatoxin | 10/20a | 10/20a | 10/20a |

| Deoxynivalenon (DON) | 5,000 | 1,000 | 500 |

| T2 toxin | – | 50 | 30 |

| Zearalenone (ZEA) | – | 400 | 200 |

| Fumonisin (B1 + B2) | 20,000 | 3,000 | 1,500 |

| Ochratoxin | 100 | 40 | 25 |

| EU (ppb) | Practical when present alone | Practical when others present | |

| Aflatoxin | 10/5a | 5 | 5 |

| Deoxynivalenol (DON) | 2,000/5,000 | 1,000 | 300 |

| T2 toxin | – | 100 | 50 |

| Zearalenone (ZEA) | 500 | 300 | 100 |

| Fumonisin (B1 + B2) | 20,000/50,000a | 3,000 | 1,500 |

Based on the information above, even at low levels, action needs to be taken when mycotoxins are demonstrated or fungi are present in the feed. Removal of the contaminated feed is often not the most economical solution. The qualitative and quantitative determination of the mycotoxin contamination level enables us to choose the optimum toxin binder and determine its ideal dosage. Additionally, the use of supporting agents like betaine and natural antioxidants can help reduce the negative effects of mycotoxins and promote the recovery of affected organs. Regularly monitoring feed and consequently dealing with mycotoxins results in healthy animals, leading to increased production results and therefore better economic results.

Would you like to be kept informed of our latest developments? Register here and stay up to date.

"*" indicates required fields

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |