For many cattle operations, good quality forage has the potential to be the lowest input feed cost. However, a poorly managed bunker, pile, silage pit, or clamp can reduce the quality of the feed produced and become a flourishing environment for mold growth and the production of secondary metabolites, mycotoxins.

These performance-impacting toxins are typically found on the edges of piles, where fermentation was inadequate and air prevalent, and are at first a palatability issue but—depending on the severity and the duration of mycotoxin exposure—can easily become a health risk to cattle. Since over half of most cattle diets are forage, creating mold (and in turn toxin) free forage is essential to feed energy levels and herd health.

Building a proper bunker is the best defense against mold growth in forages, though if there is a concern, it is best to perform a mycotoxin test. Fermented forage is produced when the aerobic growth of bacteria turns oxygen into carbon dioxide with the additional output of organic acids like lactic acid, acetic acid, and propionic acid. The removal of oxygen, with the pH drop from the acids, reduces mold’s ability to grow (and consume valuable sugars). An anaerobic environment alone is not the solution—as penicillium can utilize acetic acid as a carbon source—and is why a low pH (below 5) is also valuable, especially for heat/fermentation-resistant aspergillus molds.

There is much literature on how to properly ensile forages and silages, however, a simple summary includes:

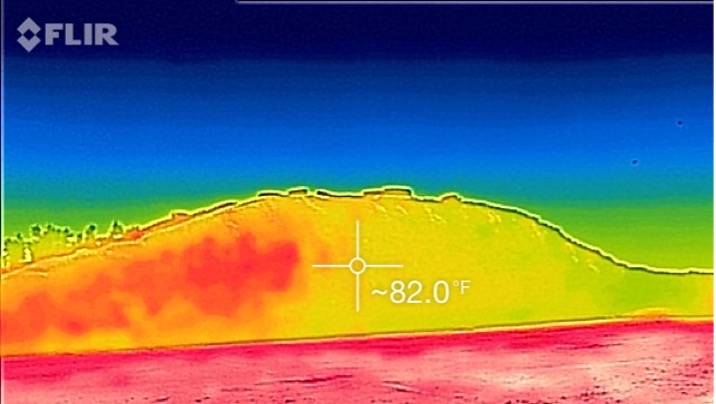

Yeast and mold are the primary culprits of heating (and sugar consumption) during feed out. As soon as the pile or bag is opened, oxygen is available to yeasts and molds for aerobic growth. Their growth has two direct impacts, energy loss and heat generation. Though it is inevitable for some oxygen to seep into a pile from the exposed face, the correct construction, density, and facing techniques can reduce the impact. The best practice for forage removal is with a shaver that uses a downward motion. Proper use of a shaver can help limit oxygen penetration to 30 cm. When using a rake or bucket attachment, the forage is lifted and pulled away from the pile, exposing at least a full meter of the forage to oxygen.

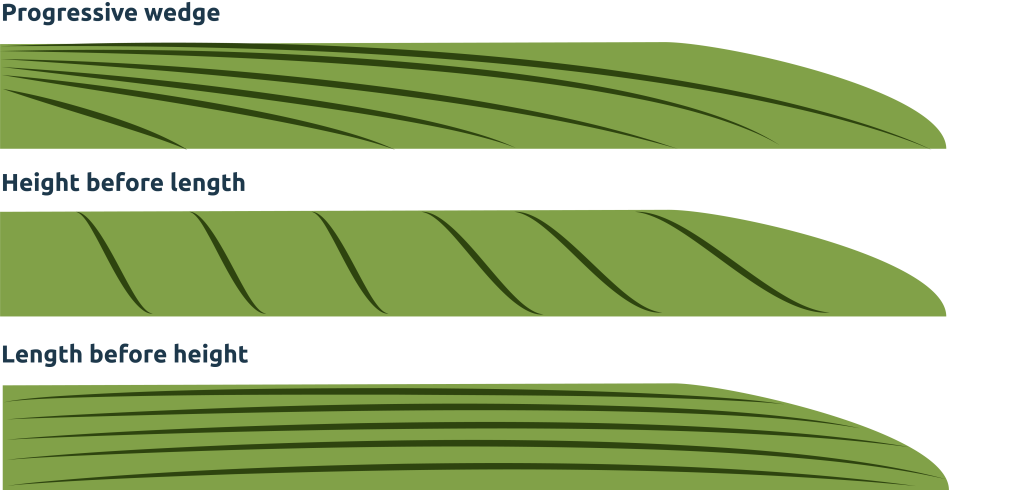

Even when all clamp-building practices are followed perfectly, it is advised to feed at least 30 cm off the entire face daily. This is why determining the size of your silage pile face is important (Figure 2).

It is rare to find a clamp or pile without some spoilage around the top or edges, discard spoiled feed as these areas are low in energy value and high in toxin risk. When pitching spoiled feed and working around bunker faces, always utilize safety first.

Finally, with effective feed out, avoid pulling excess feed from the pile or mixing once for both morning and evening feeding. Though it can be convenient to mix once, the loose feed will heat significantly and result in lower feed intake, especially in warm weather when cattle already tend to go off feed.

A 3-year (2009 to 2011) survey on the worldwide occurrence of mycotoxins revealed that 81% of 7,049 livestock feed samples collected from the Americas, Europe, and Asia were positive for at least one mycotoxin (Rodrigues and Naehrer, 2012). In addition to the mycotoxins occurring in forage, when grains infected with even low levels of mycotoxins are included in the total mixed ration, the total amount of mycotoxins ingested by cows can be greater than the maximum concentrations allowed or recommended in ruminant diets by the US FDA and European Union. This is why proper forage management is important. Mold does not necessarily mean mycotoxins, as mycotoxins are produced when mold is under stress, but the ability to identify mycotoxin-producing molds is helpful in evaluating feed quality.

Would you like to be kept informed of our latest developments? Register here and stay up to date.

"*" indicates required fields

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |