Storage fungi—typically belonging to the Aspergillus and Penicillium genera—contaminate raw material or feed during storage, transport, or processing. In these stages, growth depends on the moisture level, damage to the grains, the entrance of water, temperature fluctuations, etc. Though there are many factors, basic preventive measures can be taken to reduce the risk of mycotoxins found in feed.

Avoid mixing clean grain with dirty grain and limit exposure to reduce the risk of mycotoxin contamination. During transportation, there is a low risk of mycotoxin transfer, but it is good practice for trucks and containers to be emptied completely between loads. Ideally, they are swept too.

The same goes for bins and other large, long-term storage containers. If an ‘all-in all-out’ policy cannot be achieved, empty the bin as much as possible before adding new grain. Follow safety standards when working in/around bins. With this, consider proper handling of grains, as broken or damaged hauls expose the saccharides in the grain to molds and fungi.

Perhaps the most impactful way to mitigate the risk of molds, and the potential for mycotoxins, is to reduce the moisture content of the grain as soon as possible after harvest. Drying wheat and corn to 14% and 15% moisture will limit spoilage and potential fungal growth. Though it can be a challenge based on the ambient temperature at harvest, allow the grain to cool after drying. The reason is similar to putting food in the refrigerator, mold activity is typically reduced in cool environments.

Once the grain is sufficiently dry and cool—but before being placed into an empty, clean, and dry storage area free of holes—a fungicide can be applied. Applying a treatment may reduce mold growth, preserving the grain’s nutritional value—as molds consume valuable sugars—and decrease the risk of mycotoxin production by stressed mold. However, this fungicide will only eliminate existing molds/fungi, not mycotoxins.

Each toxin has its preferred environment, and controlling the storage environment is the next step to reducing the risk of mycotoxins.

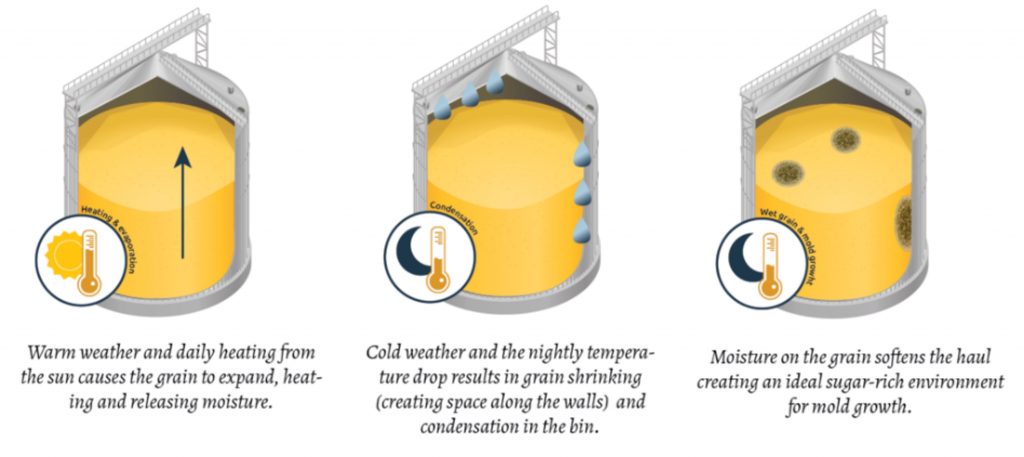

At the level of feed factories, especially in the silos, fungi mostly grow where humidity is prevalent. These points occur via the movement of moisture from the silo’s exterior, particularly at night when ambient temperatures drop. The temperature change produces condensation on the internal walls of the silo, which promotes the growth of fungi (Figure 1). The same phenomenon can occur in trucks, shipping containers, and other compartments where grain or feed is stored.

To avoid this fluctuation and condensation build-up, temperature and humidity control need to be considered. This can be achieved with ventilation to avoid heat and moisture.

Pests—like rodents, birds, and flies—can be reduced by sweeping and discarding excess grain on the ground and ensuring grain is stored in a space with no holes. Regularly cleaning the area surrounding the bin and not allowing weeds to grow against the bin is imperative.

If contamination does occur, remove tainted grain to prevent further spread. Despite preventive measures, most feedstuffs are contaminated by at least one mycotoxin in the field, and the amount exponentially increases by the time it reaches the farm. In addition to proper storage strategies, accurate sampling and a scientifically proven toxin binder are critical to protecting animals against the adverse risks of mycotoxins.

Would you like to be kept informed of our latest developments? Register here and stay up to date.

"*" indicates required fields

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |